Construction, Engineering, Real Estate

How to Minimize Construction Waste on Site: A Complete Guide

Construction waste has become one of the biggest challenges in the building industry today. Every project, whether it is a small renovation or a large-scale development, produces leftover materials that often go unused. Piles of broken concrete, unused bricks, splintered wood, bent metal rods, and heaps of packaging materials are all too common on sites. While these may seem like small losses at first, they accumulate quickly, leading to enormous amounts of waste that eat into profits and harm the environment.

The truth is, most of this waste is avoidable. Poor planning, careless handling of materials, and lack of awareness among workers are some of the main causes. If you have ever stepped onto a construction site covered in debris, you have probably asked yourself whether all of that waste was really necessary. The answer is almost always no. With the right strategies, construction waste can be reduced dramatically, saving both money and time.

Reducing waste is not just about tidying up the site. It is about embracing a smarter way of building. Every material that goes to waste represents lost money, wasted energy in production, and added strain on the environment. Imagine pouring your resources into buying top-quality materials, only to see a large portion end up in the trash. It is like filling a bucket with holes.

The need for waste reduction is more urgent now than ever. With rising construction costs, stricter environmental regulations, and growing demand for sustainable practices, companies that ignore waste management risk falling behind. Clients are also becoming more conscious of eco-friendly building practices. A contractor who shows responsibility in managing waste stands out as professional and forward-thinking.

So, how can we turn this problem into an opportunity? By understanding the root causes of waste and applying practical solutions, construction teams can build smarter, save more, and protect the planet at the same time. This guide will walk you through the eight wastes of construction, their impact, and proven methods to minimize them. In the end, you will see that managing waste is not a burden but a pathway to efficiency and success.

Understanding Construction Waste

Before we can reduce waste, we first need to understand what it actually is. Construction waste refers to all the unwanted materials that are left behind during building, renovation, or demolition projects. These materials are not just limited to large debris like broken concrete or unused bricks. They also include smaller items such as packaging from materials, excess paint, offcuts of wood, bent nails, and even dust and dirt from excavation.

On a typical site, you will find piles of rubble, heaps of wood scraps, bags of cement hardened by moisture, and rolls of unused wiring. All of this counts as construction waste. The problem is that much of it ends up being discarded rather than reused or recycled. In many cases, materials are wasted not because they are unusable but because they were ordered in excess, mishandled, or poorly stored.

Think of construction waste as a hidden leak in your project budget. Every nail, brick, or bag of cement that goes unused is money that could have been invested elsewhere. Beyond money, this waste consumes energy and natural resources. For example, the production of cement is energy-intensive, and when unused bags are thrown away, the energy that went into making them is wasted too.

The more we recognize the different forms of waste on-site, the better equipped we are to tackle them. Some waste is inevitable, but a large percentage is preventable. By learning to spot where and how waste is created, contractors and workers can take simple but effective steps to reduce it.

What Are the 8 Wastes of Construction?

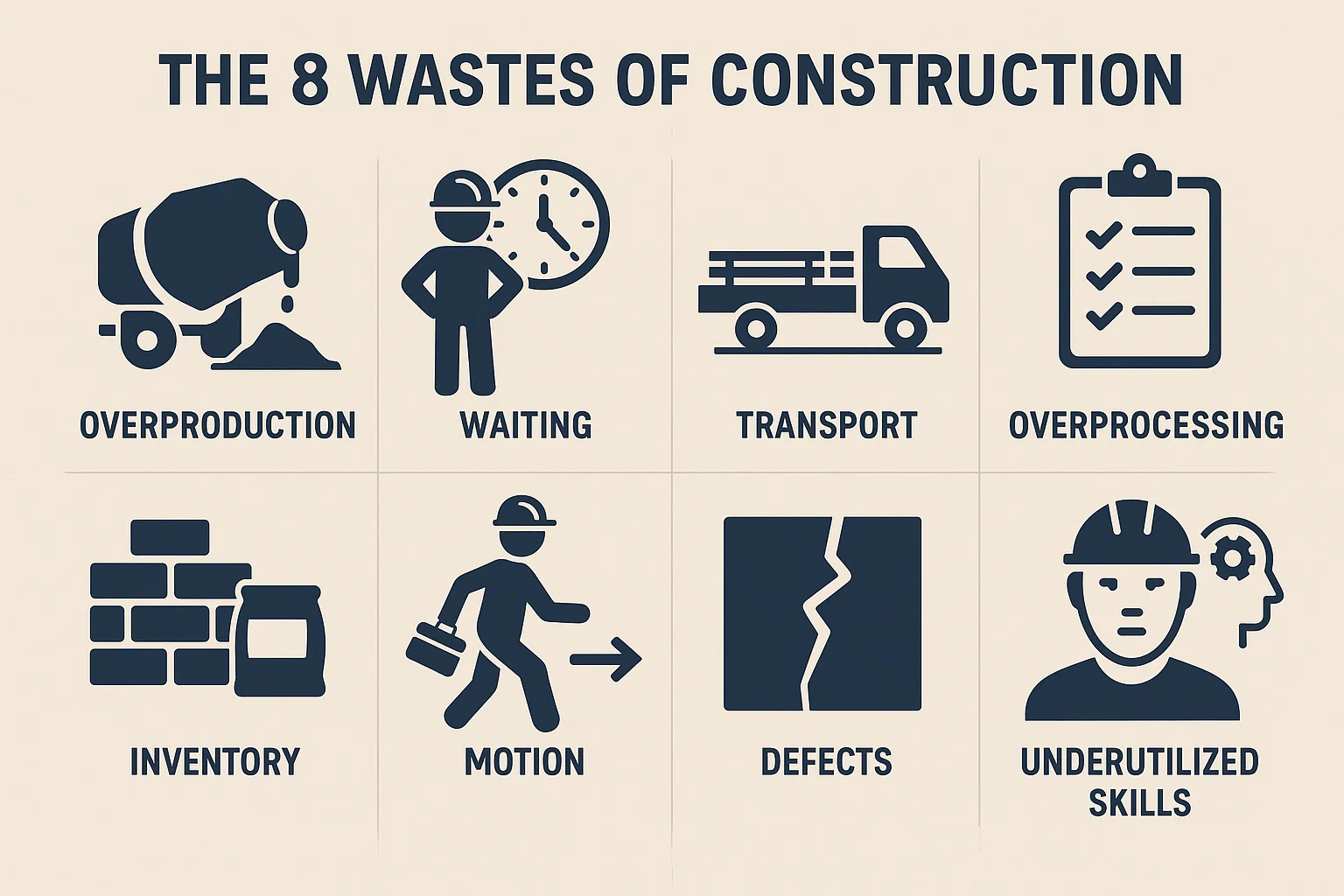

In construction, waste is not just about piles of leftover materials. Sometimes, waste comes in the form of lost time, unnecessary movements, or underused skills. To make waste management practical, the industry often uses the concept of the 8 wastes of construction, which was inspired by lean manufacturing principles. These wastes highlight the main areas where resources slip through the cracks. Once you learn to spot them, you begin to see just how much can be saved by working smarter.

1. Overproduction

Overproduction happens when materials or work are done earlier or in larger quantities than needed. For example, mixing too much concrete at once or fabricating extra steel components. This often leads to spoilage or unnecessary storage costs. Overproduction ties up resources and reduces flexibility in managing projects.

2. Waiting

Time is one of the most valuable resources on a construction site. Yet many hours are wasted because workers are waiting for instructions, materials to be delivered, or approvals to move to the next stage. Every minute spent waiting is lost productivity, and these delays can add up to days or even weeks over the life of a project.

3. Transport

Transport refers to the unnecessary movement of materials around a site. When materials are delivered far from where they are actually needed, workers end up spending extra time carrying or hauling them. This not only slows down work but can also damage fragile materials in the process. Imagine carrying tiles back and forth across a site simply because they were stored in the wrong place.

4. Overprocessing

Sometimes projects involve more work than is necessary. Overprocessing could mean doing double inspections when one would be enough or applying finishes that are not required by the client. This type of waste consumes both time and money without adding value to the project.

5. Inventory

Excess inventory is another major cause of waste. Ordering too many bricks, tiles, or bags of cement may seem like a safe strategy to avoid shortages, but when they go unused, they become dead stock. Often, extra materials are left exposed to weather, leading to spoilage. The irony is that in trying to avoid delays, companies end up wasting money.

6. Motion

Motion waste occurs when workers or equipment move more than necessary. For example, if tools are stored too far from where they are being used, workers spend valuable time walking back and forth. Over time, these small movements accumulate into significant lost productivity. It is like watching your team spend half their energy just looking for what they need instead of doing the actual work.

7. Defects

Defects are mistakes that require rework or result in wasted materials. Poor measurements, incorrect installations, or using the wrong materials often lead to this kind of waste. Rework not only consumes extra materials but also stretches the timeline of a project. Every error made is time and money lost.

8. Underutilized Skills

Perhaps the least obvious but most damaging waste is failing to use workers’ skills to their full potential. When skilled workers are given tasks that do not match their abilities, their talent is wasted. For example, having an experienced engineer spend hours doing paperwork instead of focusing on technical solutions reduces the value they bring to the project.

The 8 wastes of construction serve as a mirror, reflecting the inefficiencies that occur daily on-site. While some of them may not produce physical waste, they all create hidden costs that reduce profitability and efficiency. By recognizing these wastes, teams can start to address them systematically and create a culture of continuous improvement.

The Impact of Construction Waste

Construction waste is not just an inconvenience on-site. It creates serious consequences that ripple across the environment, the economy, and even society. When waste is not managed properly, it leaves behind costs that go far beyond the project itself.

1. Environmental Concerns

Most construction waste ends up in landfills, where it takes up valuable space and contributes to pollution. Materials like plastics and treated wood release harmful chemicals into the soil and water. Dust and debris can also affect air quality around the site, creating health risks for nearby communities. The production of new materials to replace wasted ones requires energy and natural resources, increasing carbon emissions and harming ecosystems.

2. Financial Losses

Every bag of cement, stack of bricks, or roll of steel that goes unused represents money wasted. Contractors often face tighter budgets, and even small losses add up quickly. Rework caused by defects is especially costly because it involves paying for both labor and materials twice. Waste also drives up disposal costs since removing and transporting debris requires additional resources.

3. Social Impact

Poor waste management damages the reputation of builders and contractors. A site filled with debris looks unprofessional and unsafe. Communities living near construction projects may also experience noise, dust, and blocked access, leading to frustration and complaints. In some cases, mismanaged waste can result in legal issues if regulations are ignored, creating further problems for both contractors and clients.

Top Strategies to Minimize Construction Waste on Site

Minimizing construction waste requires more than good intentions. It calls for deliberate strategies that guide how projects are planned, executed, and completed. By taking practical steps, builders can cut waste significantly while saving time and money. Below are proven strategies every project team should adopt.

1. Careful Planning Before Construction

Waste reduction begins long before the first brick is laid. A detailed project plan identifies exactly what materials are needed and when they will be used. This prevents last-minute purchases that often result in excess inventory. A clear schedule also ensures materials arrive on time, reducing the risk of damage from prolonged storage. Good planning also considers the sequence of tasks so that work flows smoothly with minimal interruptions.

2. Accurate Material Estimation

Ordering the right amount of materials is one of the most effective ways to prevent waste. Overestimating leads to surplus stock that may never be used, while underestimating creates delays that force quick and often costly purchases. Accurate estimation can be achieved through detailed drawings, quantity surveys, and digital tools that calculate requirements precisely. Contractors who invest time in this step often save large amounts in the long run.

3. Standardizing Measurements

Standardization reduces unnecessary cutting and offcuts. For example, designing rooms with dimensions that match the standard size of tiles or plasterboards minimizes the amount of trimming required. When dimensions align with material sizes, every unit is used more efficiently, leaving little to throw away.

4. Efficient Site Organization

How materials are stored and handled on-site has a direct impact on waste levels. Cement bags left exposed to moisture harden and become useless. Tiles stacked carelessly break before they are even used. Setting up designated storage areas with proper protection ensures materials stay in good condition. Clear labeling and organized storage also reduce the time workers spend searching for items, improving productivity while lowering the risk of damage.

5. Clear Communication with Suppliers

Suppliers play an important role in reducing waste. Clear instructions about delivery times, packaging preferences, and quantities help avoid mistakes. For instance, requesting deliveries in smaller batches ensures materials arrive only when needed, reducing storage problems and the risk of spoilage. Collaborating with suppliers to reduce unnecessary packaging also lowers the volume of waste generated.

6. Using the Right Equipment

Waste often occurs when tools and equipment are not suited to the task. The wrong cutting tools can ruin tiles or metal sheets, creating avoidable losses. Providing workers with the correct equipment ensures materials are cut, shaped, and installed with precision, reducing errors and defects.

7. Regular Site Inspections

Frequent checks help identify areas where waste is occurring. Inspections highlight issues such as poor material handling, incorrect installations, or excess inventory. By addressing these problems early, contractors prevent small mistakes from turning into bigger, costlier losses.

8. Assigning Responsibility

When no one is accountable, waste goes unnoticed. Assigning waste management responsibilities to specific individuals ensures the team remains focused. A site supervisor can track material use, monitor waste segregation, and ensure that disposal practices are followed correctly.

These strategies may seem simple, but their combined effect is powerful. A well-organized, carefully planned project minimizes waste, saves money, and ensures smoother operations. Waste reduction is not about doing more work. It is about working smarter and respecting every resource that enters the site.

Reusing and Recycling Construction Materials

One of the most effective ways to minimize construction waste is to view leftover materials not as trash but as valuable resources. Reusing and recycling extend the life of materials, reduce disposal costs, and protect the environment. Instead of sending everything to a landfill, construction teams can find practical ways to give materials a second life.

1. Materials That Can Be Reused

Many construction materials are perfectly suitable for reuse with little or no processing.

Concrete: Broken concrete can be crushed and used as a base for roads, pavements, or new foundations.

Wood: Offcuts and surplus timber can be repurposed for formwork, scaffolding, or even furniture projects.

Steel and Metals: Reinforcement bars, pipes, and other metal scraps can often be cut, reshaped, and used again.

Bricks and Blocks: Intact bricks from demolition can be cleaned and reused in non-structural walls or landscaping.

Glass: Window glass can sometimes be resized for other installations.

Reusing saves money by reducing the need to buy new materials and also prevents waste from piling up on-site.

2. Recycling for Greater Efficiency

When reuse is not possible, recycling is the next best option. Recycling involves processing materials so they can be used in new products. For example:

Concrete can be crushed and recycled into aggregate for new mixes.

Metals such as steel and aluminum can be melted down and reformed without losing strength or quality.

Plastics used in piping or packaging can be shredded and recycled into new construction materials.

Asphalt from old roads can be reused in new paving projects.

Recycling reduces the demand for raw materials, which means fewer natural resources are extracted. It also lowers the environmental footprint of construction projects.

3. On-Site Segregation of Materials

For reuse and recycling to work efficiently, materials must be sorted properly at the site. Mixing concrete debris with wood or plastics makes recycling difficult and expensive. Setting up separate bins or areas for different waste types ensures that materials remain clean and ready for processing. Clear signage and training for workers make this system easier to follow.

4. Economic and Environmental Benefits

Reusing and recycling materials significantly lower disposal costs. In many cases, recycled materials can even generate income if sold to recycling companies. Environmentally, the benefits are equally powerful. Recycling reduces the demand for landfill space, lowers carbon emissions, and conserves natural resources.

5. Building a Culture of Reuse and Recycling

For these practices to succeed, they must become part of the site culture. Workers need to see materials as assets rather than disposable items. Simple actions such as setting aside reusable timber or collecting scrap metal for recycling create long-term savings and improve project sustainability.

Reusing and recycling turn waste into opportunity. Instead of paying to throw away valuable resources, contractors can save money, reduce environmental impact, and showcase their commitment to sustainable construction.

Construction Waste Disposal Best Practices

Even with careful planning, accurate estimation, and reuse strategies, some waste will always remain on a construction site. What matters is how that waste is handled. Proper disposal is not only a legal requirement in many regions but also a mark of professionalism. Following best practices ensures safety, compliance, and environmental responsibility.

1. Sorting Waste on Site

Segregation is the first step toward effective disposal. Materials should be sorted into categories such as wood, metal, concrete, plastics, and hazardous waste. Mixing everything together makes recycling difficult and often leads to higher disposal costs. Clear labeling of bins and designated disposal areas make it easier for workers to follow the system.

2. Handling Hazardous Waste Carefully

Some construction materials are hazardous to people and the environment. These include asbestos, certain adhesives, paints, solvents, and treated wood. Such materials require special handling, storage, and disposal methods. Failure to manage them correctly can lead to health risks, legal penalties, and environmental damage. Contractors should always work with licensed handlers for hazardous waste.

3. Partnering with Licensed Disposal Companies

Not all waste can be reused or recycled on-site. This is where licensed disposal companies play an important role. These companies have the expertise and equipment to manage construction waste in a safe and compliant manner. Partnering with them ensures that waste is handled legally and responsibly.

4. Keeping Disposal Records

Maintaining records of how waste is disposed of is both a compliance measure and a best practice for accountability. These records may include receipts from disposal companies, recycling certificates, and internal waste tracking logs. They not only prove that the project meets legal requirements but also highlight areas where future waste reduction is possible.

5. Minimizing Packaging Waste

Packaging materials often account for a significant portion of construction waste. Cardboard boxes, plastic wraps, and pallets pile up quickly if not managed properly. Contractors can reduce packaging waste by requesting suppliers to use minimal or reusable packaging. Returning pallets and containers to suppliers also helps cut disposal volumes.

6. Scheduling Waste Removal

Waste should not be allowed to accumulate on-site. Regular removal ensures the site remains safe, organized, and productive. A scheduled waste collection system avoids last-minute rushes and prevents hazards caused by cluttered work areas.

7. Encouraging Worker Participation

Waste disposal works best when every worker is involved. Training sessions and clear communication about waste policies help build awareness and accountability. When workers understand that proper disposal keeps the site safer and more efficient, they are more likely to follow best practices consistently.

Effective waste disposal is more than cleaning up after construction. It is about creating a system that respects the environment, protects workers, and meets regulatory requirements. A site that manages waste responsibly not only saves costs but also builds trust with clients and communities.

Conclusion

Construction waste is a silent budget killer and a huge environmental burden. By understanding the 8 wastes, planning better, training workers, and embracing modern technologies, you can significantly minimize waste on site. Sustainable construction is not just the future. It is the present.

At Nyolenju Structures, we believe in smart designs that reduce waste from the very beginning. With detailed and compliant house plans, we help you build efficiently, save money, and protect the environment. Ready to start your next project with less waste and more value? Let us design your dream today.

FAQs

1. How can small contractors minimize waste?

By carefully estimating materials, reusing leftovers, and training workers to handle resources responsibly.

2. What is the most common type of construction waste?

Concrete, bricks, and wood are the most common.

3. Can construction waste be profitable?

Yes, recycled materials like steel and crushed concrete can be sold or reused, saving money.

4. What are examples of recyclable construction materials?

Steel, wood, glass, concrete, and plastics are recyclable.

5. How can house designers help reduce construction waste?

By creating accurate and detailed plans, they ensure efficient material use and reduce unnecessary purchases.